Prototypes

Prototypes from CC Plast

Utilizing prototypes from CC Plast eliminates costly investments in production tools until the final design is confirmed. This not only reduces risks but also shortens the project timeline.

We specialize in creating prototypes, including milled, injection molded, and 3D printed prototypes. By integrating these methods, we ensure that our customers can evaluate and refine the design, resulting in optimal functionality and quality, while achieving significant savings in both time and investments.

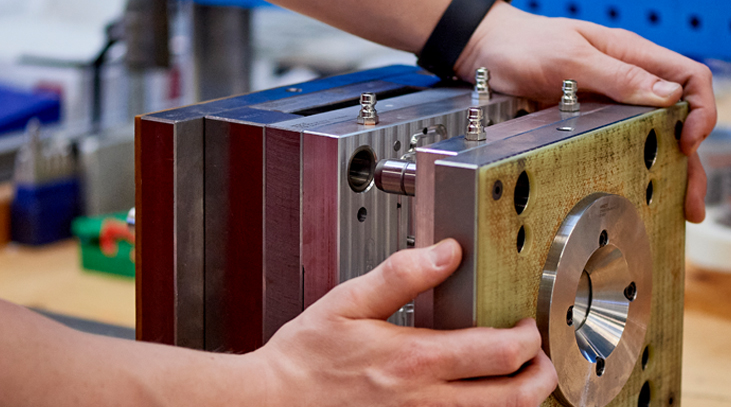

Injection Molded Prototypes

These prototypes are manufactured in a trial tool designed to enable production in a standard injection molding machine.

As a result, the prototypes accurately replicate the same design and properties as an item produced in a final production tool. This allows for various tests, such as material selection, design validation, and market analysis. Moreover, prototypes offer a flexible solution, especially when only a limited quantity of items is needed. This approach ensures realistic test results and enhances efficiency in the development process by minimizing risks and costs associated with early production stages.

3D Printed Prototypes

CC Plast utilizes advanced 3D printers capable of producing complex items with a layer thickness of 40 micrometers. Using 3D files, we can create an accurate physical replica of your design.

This technology enables rapid and cost-effective reproduction of your item, suitable for presentations to stakeholders, customers, and evaluation of the item’s functionality. With this advanced printing technique, we offer an efficient solution that accelerates the development process and ensures precise prototypes to support decision-making and product assessment.